Important findings for the development of steel formwork

Optimization of steel formwork (Ibaraki Prefecture, JP)

JFE Civil Engineering & Construction Corp.

Optimization of steel formwork

Description

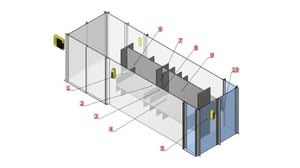

This project report showcases the successful integration of PERI InSite Construction / PHONO Concrete Detection and Compaction Monitoring at the construction site of MFLP Tsukuba-Mirai in Ibaraki Prefecture, Japan. The project, carried out by JFE Civil Engineering & Construction Corp., focused on optimizing the construction of the PCa (Pre-cast Concrete) steel column formwork.

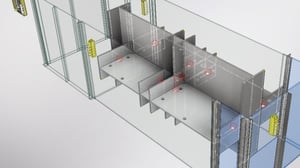

The filling and compaction sensors were installed in the mock-up formwork during concrete pouring. The mock-up formwork also served as the testing ground for this innovative technology, marking the first official commission of PERI ISC / PHONO by JFE Civil Engineering & Construction Corp.

Challenges

The primary objective was to verify the adequacy of concrete filling beneath the steel stiffener within the mock-up column formwork.

Solution and results

Sensors were strategically positioned at 10 locations within the mock-up steel formwork to monitor concrete filling and compaction. The sensors were installed in the formwork using suitable fastening material. Careful positioning of the sensor cables minimized obstructions during concreting and concrete compaction. The ISC nodes were strategically placed on the steel formwork to allow easy removal and retrieval of data.

The measurement results were in line with expectations and showed effective monitoring of concrete filling and compaction throughout the concreting process. Continuous monitoring enabled real-time adjustments, contributing to the success of the project. Independent assessments confirmed the accuracy of the sensor readings and validated the effectiveness in assessing the concrete fill. Positive feedback from JFE Civil Engineering & Construction Corp. underpinned the success of the initiative and positioned the sensor solution as a reliable solution for construction monitoring and efficiency improvement.

- 11,75 m Fassadenstützen in SB 4 Sichtbetonqualität

aus Weißbeton

- individuelle Sonderschalungslösungen

- Unterstützung und Schulung des Baustellenpersonals bei der Umsetzung der komplexen Geometrien und Formen

- Termingerechte Materialbreitstellung und Koordination der Liefertermine

Curious?

We will present the solution to you in a 20-minute online demo without any obligation.