Reference Projects

-

All

-

PHONO

-

TEMO

-

PREMO

-

SONO

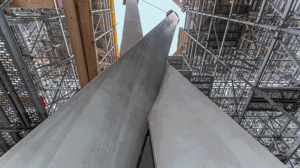

Concrete detection sensor tech enabled real-time concrete monitoring, ensuring precision, safety, and speed during the record 18-day bridge installation with minimal disruption and full digital traceability.

Read More

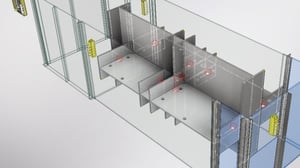

The Festhalle Bern, a multifunctional hall spanning 4,300 m², was constructed in two phases due to its height. Concrete pressure and temperature monitoring optimized the pouring process and minimized stripping time, ensuring a swift and secure construction.

Read More

The Broadway Subway Project extends Vancouver's Millennium Line by 5.7 km, featuring innovative PREMO pressure sensors that reduce concrete pour times by up to 30%.

Read More

This project report showcases the successful integration of PERI InSite Construction / PHONO Concrete Detection and Compaction Monitoring at the construction site of MFLP Tsukuba-Mirai in Ibaraki Prefecture, Japan.

Read More

SONO Sensor for rapid water cement ratio readings

Read more

Open the black box of your construction sites and benefit from more safety, speed and quality.

Contact usCurious?

We will present the solution to you in a 20-minute online demo without any obligation!