A 30% Reduction in Concrete Pour Time with Pressure Sensors

B.C. Ministry of Transportation and Infrastructure

Broadway Subway Project

Description

The Broadway Subway Project is a 5.7 km extension of the Millennium Line, providing Vancouver with fast, frequent and convenient Skytrain service across the city. It is a mix of elevated and tunnel train system with six underground stations.

Challenges

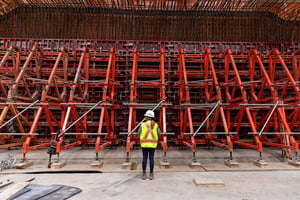

The station boxes for key stations at Broadway-City Hall and Great Northern Way-Emily Carr incorporate single sided tall walls to the lower and upper halls. Concrete pressure is a critical factor as the combination of the size, height and restrictions on placement speed result in long pour duration.

Solution and results

The use of the PREMO pressure sensors on critical pours provided the information needed to accelerate pours while staying within safe pressure limits. In optimal conditions this resulted in savings of 30% of pour duration, saving hours of labor and overtime costs. In applications on challenging pours, or when other factors have caused significant delays, the clear and actionable data gave opportunities to react efficiently and responsibly, enabling safety and quality to be managed effectively while pours continue.

- 11,75 m Fassadenstützen in SB 4 Sichtbetonqualität

aus Weißbeton

- individuelle Sonderschalungslösungen

- Unterstützung und Schulung des Baustellenpersonals bei der Umsetzung der komplexen Geometrien und Formen

- Termingerechte Materialbreitstellung und Koordination der Liefertermine

"Sensors were beneficial to increase pour rate in concrete elements where constructability issues arise due to low formwork design pressures.

We were estimated to complete the pour at 9pm but were able to complete by 4.30pm.

Great to see use of sensors rather than relying on a formula."

Curious?

We will present the solution to you in a 20-minute online demo without any obligation.