PREMO

Your speedometer for concreting speed

Multiple, vertically arranged pressure sensors allow you to keep an eye on the concrete pressure at all times and optimize the concreting speed for more safety on the construction site and an excellent concrete result.

Product features

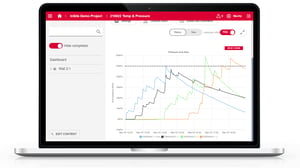

Intuitive dashboard with alarm function

Monitor sensor data in real time and analyze it in a well-organized graph. Also receive notifications for predefined, critical concrete pressure conditions.

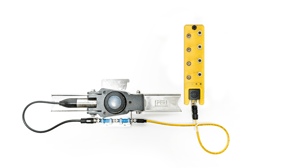

Precise pressure sensors

The body of the reusable sensors is 3D printed and extended with two stainless steel levers, which serve to protect the actual sensor and as a disassembly aid.

The concrete in the formwork exerts pressure on the central membrane of the sensor. With each addition of concrete, this pressure increases continuously until the concrete begins to harden.

Simple assembly

For quick and easy installation, the PREMO pressure sensors are supplied with a comprehensive mounting kit.

A few steps to successful measurement

Connect the sensors to a "measuring node". This automatically sends the data to the hub which forwards it to the web application.

The concreting starts, control the concreting speed via the formwork pressure. The data can be analyzed in real time on the hub and in the web app. Limits can be defined in the web app, making analysis even easier.

Proven on construction sites

“Even with hot water mixes the theoretical rate of rise was 180mm per hour. Working with PERI we were able to monitor the pressure from the very start and were quickly reaching a pour rate of 615mm per hour, without coming close to the pressure limits of the formwork. The maximum pressure was 36kPa on a 50kPa shutter – we could then maximize our loads per hour, finishing the pour in 9.5 hours rather than the theoretical 32.5 hours. We will be using the system again.”

Curious?

We will present the solution to you in a 20-minute online demo without any obligation.

You have a project and want to get started quickly?

Our sales team will be happy to advise you and prepare an individual offer for your project.